What’s Going on at Wise Ag?

Get added to the FETF farm grant email alert

Get email alerts and application guides to the 2025 FETF farm grant scheme.

On February 25, 2025, the RPA announced it will be opening another round of its Farming Equipment and Technology Fund farm grants for livestock farmers.

Farm grants between £1,000 and £25,000 will be available, with a total of £16.7 million budgeted for animal health and welfare.

In the previous three rounds of the FETF farm grant schemes, this has included upwards of 40% funding on key items such as:

Manual cattle crush

Hydraulic cattle crush

Mobile cattle handling system

Mobile sheep handling system

Load bars for cattle crush

Sheep weigh crate

EID reader

Cow brushes

In-field weighing system

If you wish to receive an email alert and guide to application once the grant has been announced, please click the below button and fill out the form.

The application guide will be relevant to all FETF farm grant applicants, with further criteria highlighted for livestock handling equipment.

Reduce concentrate inputs in store lambs by 45% while maintaining DLWG with controlled supplementation

Wise Agriculture is the UK agent for Advantage Feeders (previously known as 3 in 1 Feeders). Learn about Advantage Feeders and see the full range here.

Sheep farmers looking to hit spring market premiums in store lambs and reduce supplement feed costs will benefit from controlled supplement feeding, says Gerard Roney of Advantage Feeders, formerly known as 3 in 1 Feeders.

“The most effective way to optimise both your lamb and homegrown forage performance is by little and often feeding a small amount of starch feed such as cereals or pellets throughout the day,” explains Mr Roney. “By controlling the intake of supplemented feed, rumen conditions are stabilised and microbes develop to improve digestion and feed utilisation.”

Working with a 3-way restriction system that controls the height, width and depth of where feed sits, farmers can control feed intakes and provide it in little and often quantities with Advantage Feeders.

“In a restricted setting, stock requires saliva on their tongue to lick the feed. Stock can only feed for about five minutes until their saliva dries up. They will then go graze for about an hour before repeating the process,” explains Mr Roney.

This method of controlled supplementation has been found in farm trials to decrease the consumption of growing grass by one-third, while maintaining growth rates, allowing for a stocking density increase by 50%. Increased rumen efficiency has also been shown to decrease supplementation intake by 33% when grazing dry pasture while maintaining growth rates.

In an Advantage Feeder farm trial, it was found that livestock grazing dry pasture require 45% less supplement through the controlled little and often system compared to trough feeding every second day. This way of controlled feeding offers sheep farmers an economical option for supplementing lambs for premium markets.

“Store lambs require around 3.5% of their body weight in dry matter per day, with forage requirements quickly increasing as they get bigger. The ability to maintain growth rates on fewer feed inputs gives producers a lot more management scope to increase stocking density and to make selling decisions based on market conditions and not forage availability,” says Mr Roney.

These efficiencies are achieved as a result of optimising rumen conditions for improved digestibility and feed utilisation. According to Mr Roney, the added supplement increases microbial populations and decreases rumen passage rate to increase the energy extracted from feed stuffs and lower forage intake – making it a better supplementation option for both economic and flock health benefits.

In an Advantage Feeder farm trial, it was found that livestock grazing dry pasture require 45% less supplement through the controlled little and often system compared to trough feeding every second day.

“Traditional supplementation methods such as ad-lib feeding or once a day feeding lead to overconsumption of high starch feed in a short amount of time, which throws off rumen pH and kills off rumen microbes. This can take 24 hours to stabilise and for microbes to rebuild and return to digesting pasture,” explains Mr Roney. “Best case scenario, there’s an unnecessary amount of feed consumed to fill the energy gap caused by the rumen not fully utilising forage. The worst case scenario is losing stock to acidosis.”

Strategic supplementation

While pasture is the cheapest form of feed on farms, quality will decline towards the end of the grazing months and over winter. Strategic supplementation will yield a ROI by stretching forage stocks and filling nutritional gaps.

“Along with providing additional energy to growing lambs to help hit finishing weights for early spring markets, controlled supplementation is going to support rumen function so poorer quality forages are more efficiently digested,” concludes Mr Roney.

Qualifying items for the 2024 Farming Equipment and Technology Fund for Animal Health and Welfare grant

The RPA announced the 2023 Farming Equipment and Technology Fund for Animal Health and Welfare items will be opening in March. Here’s everything you need to know about qualifying cattle, sheep and weighing equipment.

On February 20, 2024, the RPA announced there will be a 2024 Farming Equipment and Technology Fund for Animal Health and Welfare.

The RPA has not confirmed opening, application and equipment delivery dates, however, has given the below expectations for Animal Health and Welfare items:

Application opening date: March 20

Application closing date: May 1, 2024 at 12pm

Equipment received deadline: TBD

This guide will be updated with exact dates once confirmed by the RPA.

Funding available: Minimum grant of £1,000 and a maximum of £25,000 within the Animal Health and Welfare theme. The RPA have significantly increased funding with 50% contributions on individual items.

Recipients will be chosen based on a scoring system. Providing evidence of discussing your application with a veterinarian can boost your application score by 20%.

Future product availability: Wise Agriculture has regular shipments of cattle and sheep handling equipment arriving to ensure product availability. We are already communicating with suppliers on plans to increase stock supply to fulfil any orders through the demand period. We advise you place an order as soon as you have been accepted to allow for delivery and installation well ahead of the deadline.

Livestock items that qualify

This guide will outline qualifying items fulfilled by Wise Agriculture in the following order:

Sheep (mobile sheep yards)

Cattle (cattle handling equipment and cow brushes)

Weighing and EID

Sheep

Mobile sheep handling systems

FETF number: FETF69

Grant amount: £4,881

Specifications:

250 head capacity minimum

Integrated trailer that forms part of the handling race

Road legal

20 hurdles minimum for creation of holding pen, forcing pen and a minimum of two side pens

Drafting race

Dosing race

Ability to fit footbath

Metal material construction that is either galvanised or powder coated

Note: Wood and painted materials and trailers not integrated into the system will disqualify a mobile sheep handling system

Cattle

Manual squeeze cattle crush

FETF number: FETF61

Grant amount: £2,623

Arrowlock 88 Manual Cattle Crush has new headgate lock to hold bulls

Click here for more info and to submit a quote

Specifications:

Manually operated

Full length head yoke/head gate

Crush to open on both sides for complete access to sides of animal

Sliding rear gate that is operated from outside the crush

Galvanised or powder coated metal parts

Anti-slip rubber surface on the floor

Note: Painted metalwork is ineligible

Head scoop for cattle crush

FETF number: FETF62

Grant amount: £302

Specifications:

Restrict side-to-side movement

Have a quick release function

Galvanised or powder coated metal parts

Note: Painted metalwork is ineligible Integrated head restraints supplied with a cattle crush as standard, which cannot be purchased separately and retrofitted, are not eligible under this item.

Hydraulic squeeze cattle crush

FETF number: FETF60

Grant amount: £6,590

Powerlock 108 Series Hydraulic Cattle Crush

Click here for more info and to submit a quote

Specifications:

Hydraulically or pneumatically operated

Full length head yoke/head gate

Crush to open on both sides for complete access to sides of animal

Sliding rear gate that is operated from outside the crush

Galvanised or powder coated metal parts

Anti-slip rubber surface on the floor

Note: Painted metalwork is ineligible. Manually pumped hydraulic or pneumatic systems are not eligible.

Mobile cattle handling system

FETF number: FETF56

Arrowquip has three mobile options that qualify for FETF

Click here for more info and to submit a quote

Grant amount: £8,338

Specifications:

Integrated trailer to carry all components (excluding hurdles)

Race

Crush (manual squeeze crush or manual crush)

Minimum of 10 hurdles for a gathering and holding pens

Crush requires anti-backing facility of either a sliding gate or U-shaped rump bar

Locking head yoke/head gate on crush

Rubber anti-slip surface on crush floor

Metal construction

Galvanised or powder coated metal parts

Fixed cattle handling system

FETF number: FETF57

Grant amount: £6,533

Specifications:

Two fixed metal holding pens

One circular metal forcing pen between 2.4 and 5m radius internally with covered sides

Straight or curved race measuring between 3 and 5m in length with covered sides

Sliding gate at front and back of race

Only one gate is needed if the crush has a sliding gate integrated

All metal materials with the exception of wooden rails with a minimum cross section of 150mm x 100mm within the fixed race, and within the flooring for anti-slip purposes

Galvanised or powder coated metal parts

Fixed to the ground with long-term fixtures (concrete, supporting posts)

Note: The handling system does not include the crush and a crush is not expected to be purchased as part of this item. Painted metalwork is not eligible.

Rotating cow brush

FETF number: FETF98

Grant amount: £877

Specifications:

Swinging and rotating cow brush

Auto start/stop

Swinging brushes for calves

FETF number: FETF99

Grant amount: £521

Specifications:

Swinging and rotating calf brush

Auto start/stop

Weighing and EID

EID panel reader for sheep

FETF number: FETF74

Grant amount: £793

Specifications:

Static or race reader

Antenna or Bluetooth connection

Read HDX and FDX B tags

Must be permanently fixed to the sheep handling system

EID panel reader for cattle

FETF number: FETF68

Grant amount: £795

Specifications:

Static or race reader

Antenna or Bluetooth connection

Read HDX and FDX B tags

Must be permanently fixed to the cattle handling system

Individual electronic weigh system (Indicator)

FETF number: FETF78CA

Grant amount: £623

Specifications:

Record and display weight on screen, track liveweight gains, access recorded information on individual animal

If relying on a mobile device for operation, mobile device must be purchased as part of item

EID and auto drafting compatible

Connect to computer or mobile device to download information

Note: Load bars are a separate item. Group and average weighing systems are ineligible

Weigh bars and weigh platforms for weighing livestock

FETF number: FETF79CA

Grant amount: £457

Specifications:

Electronic load bars or electronic weigh platform

Operate with digital weigh heads (indicators) or readers

For cattle crushes or batch weighing sheep or pigs

HD type load bars weighing up to 2,000kg

Weigh bars or platform for animals less than 300kg

FETF number: FETF80CA

Grant amount: £550

Specifications:

Electronic load bars or electronic weigh platform

Operate with digital weigh heads (indicators) or readers

For use with sheep races, sheep crates or pig crates

HD type load bars weighing up to 500kg

EID handheld device (stick reader)

FETF number: FETF82CA

Grant amount: £318

Specifications:

EID stick reader with RFID technology

Capable of scanning tags and storing tag data, with the ability to connect wirelessly to mobile phones or other devices

Will read HDX and FDX B tags

Wise Agriculture becomes the sole GB distributor for Arrowquip cattle handling equipment

Wise Agriculture has been named the Arrowquip supplier for GB. The North Yorkshire based firm has been an Arrowquip dealer since 2018.

North Yorkshire firm Wise Agriculture has been appointed sole distribution rights in England, Scotland and Wales for Arrowquip’s cattle handling equipment portfolio.

The appointment will drive innovations and enhance customer care for the GB market says Arrowquip’s UK Manager Darren Brennan.

“Arrowquip’s mission is to improve the safety and efficiency of cattle handling by providing the farming community with equipment that combines world-class engineering with designs based on practicality and animal behaviour. This is supported with industry-leading warranties of up to 15 years on some crush models and a customer-first approach to follow-up support and care,” says Mr Brennan. “Wise Agriculture shares this mission and has been instrumental to Arrowquip’s development for the UK and customer service.”

After seeing a need in the industry for quality livestock equipment supported by quality customer service, livestock farmers Edward and Laura Wise established Wise Agriculture in 2018 with their first shipment of Arrowquip manual squeeze crushes from the Canadian company. Their business has since grown to be Europe’s largest Arrowquip importer and has also taken on sole UK distribution rights for Advantage Feeders (formerly known as 3-in-1) and Landquip NZ’s Porta-Yards mobile sheep handling range. The firm is also a leading distributor of Tru-Test weighing and EID equipment and AgriCow brushes.

“Wise Agriculture was founded on the base of efficiency, innovation, practicality and quality in both the equipment we provide and the way we conduct business. We are here to provide farmers and other stakeholders in the livestock supply chain with products built to last and customer service they can have faith in,” says Mr Wise, Managing Director of Wise Agriculture. “Arrowquip has been and will continue to be an excellent partner in upholding this ethos.”

Wise Agriculture has been Arrowquip’s distributor in Scotland since June 2023. All GB customer support will be handled by the firm who can be reached by visiting wiseag.co.uk.

Wise Agriculture appointed as the GB agent for Advantage Feeders

Wise Agriculture has been appointed GB distributor for Advantage Feeders livestock feeding systems.

Advantage Feeders will now be supplied by Wise Agriculture throughout England, Scotland and Wales. The extensive Advantage Feeders range includes grain and pellet feeder options for beef, dairy and sheep farms.

Wise Agriculture has been appointed GB distributor for Advantage Feeders livestock feeding systems.

Headquartered in Victoria, Australia, and formerly known as 3IN1Feeders, Advantage Feeders offers an extensive range of grain and pellet feeders designed to optimise productivity in beef, dairy and sheep.

“Advantage Feeders promotes ‘little and often’ controlled feeding by utilising stock’s saliva production to manage feed intakes. This improves rumen function and digestibility, which increases feed conversion rates to achieve higher output on lower feed input,” explains Gerard Roney, managing director of Advantage Feeders.

According to Mr Roney, the partnership with Wise Agriculture will support the company’s mission of providing new innovative feeding solutions to British farmers and allow it to continue to provide a high level of customer service to existing and future customers.

Based near Richmond, North Yorkshire and established in 2018 by livestock farmers Edward and Laura Wise, Wise Agriculture specializes in premium livestock handling, data recording and animal welfare solutions for beef, dairy and sheep producers. The business is the UK distributor of Landquip’s Porta-Yards sheep handling portfolio and is the primary UK dealer of Arrowquip cattle handling equipment.

“We are excited to partner with Advantage Feeders and work alongside them to enhance customer experience and availability of advanced feeding solutions to livestock producers,” says Edward Wise, managing director of Wise Agriculture. “Their commitment to quality, service and product development aligns with our company ethos as we strive to provide tools to farmers to enhance their resource utilisation and profitability.”

Since launching in the UK in 2012, Advantage Feeders have been popular options for British producers looking to maximise performance with homegrown feeds and pasture conversion.

Trial work has found Advantage Feeders to increase growth rates by 0.5kg/day in store cattle grazing fodder crops and supplemented with homegrown barley while simultaneously decreasing forage intakes by 3kg/day.

In a UK sheep trial, lambs that were creep fed with Advantage Feeders grew 9% faster than the control group, allowing the farm to achieve an 11% premium by having lambs sold three weeks earlier. Ewes fed with Advantage Feeders on the same farm were also able to have increased ewe stocking rates by 50%, for an overall profit increase of 208% compared to the control group.

“As livestock producers work to future-proof their businesses against unstable markets and challenging weather conditions, strategic investments to help them maximise homegrown feed utilisation and optimise livestock performance will be essential,” concludes Mr Wise. “We are looking forward to working with Advantage Feeders to not only deliver quality tools to help achieve this but the technical support and service for farmers to help them see a return on investment.”

11 lessons on stress-free cattle handling from Dr Temple Grandin

Here are 11 lessons Dr Temple Grandin has for British beef and dairy producers on creating stress-free cattle handling systems.

This information came from AHDB’s July 27, 2023 Webinar “Stress-free stockmanship with Temple Grandin.”

World-renowned for her work in developing low-stress livestock handling practices and livestock handling systems, Dr Temple Grandin is an industry pioneer in animal behaviour research.

Here are 11 lessons Dr Grandin has for British beef and dairy producers on creating stress-free cattle handling systems.

#1 Cattle handling has improved, but there is still room to get better

A 2020 study found:

46% of handlers overload the crowding pen

30% of handlers make too much noise

28% of handlers stand in the wrong position

All of these factors impact cattle working flow and stress levels.

#2 Calm cattle are easier to handle

Once an animal becomes fearful or excited, it takes a minimum of 20 minutes for it to become calm again, says Dr Grandin.

Some stressful events are unavoidable, such as calmly bringing cattle in from pasture to working pens.

However, agitation can be escalated or unnecessarily brought on by:

Using too much force

Making a lot of noise such as screaming, yelling and loud whistling

Waving arms and driving aids around erratically

Slipping on flooring

“Calm cattle are easier to handle. If you’re bringing cattle in from the pasture, it is worth taking a little break and allowing them to settle down before handling.”

Cattle also remember whether a handling experience was positive or negative, which will impact how easy they are to work in the future.

“When you’re handling (cattle) a lot, like TB testing, give them some treats after they go through,” says Dr Grandin. “You don’t have to feed them very much, just a taste of a treat is enough to work.”

#3 Cattle show physical signs of stress

These include:

Excessive pooping

Swishing their tails

Seeing the whites of their eyes

Vocalization during handling, including when you are restraining them

Additional panels can be added to the sides of Arrowquip’s adjustable Easy Flow cattle races to block off distractions.

#4 Distractions in the cattle handling facility will cause animals to balk and refuse to move

Common distractions Dr Grandin comes across include:

Shadows and high contrasts of light and dark

Reflections on metal or water

Shiny metal

Seeing people up ahead of where they need to move

Moving objects inside and outside the handling system

Pieces of string tied to gates and fence

Air blowing in their faces

Coats hung on fences

Objects lying on the ground

Drain grates

Changes in flooring type causing visual contrast

Dripping water

Dangling chains

Turning fan blades

#5 Lighting and shadows require extra attention to avoid balking

Shadows

Both research and Dr Grandin’s observational experience show that sharp shadows are likely to stop cattle from moving forward. An example of this would be a shed roof casting a sharp shadow across a forcing pen, causing cattle to not want to cross over it and into a race entry.

Because these have a wide range of variable causes such as cloud coverage, time of day and even a handler’s positioning, Dr Grandin recommends farmers assess their handling systems at multiple times throughout a day and in a variety of conditions.

Lighting

Cattle want to move towards light, but not blinding light, says Dr Grandin. Animals will enter into a cattle crush more easily if the entrance is lit. Because of this, it is important headgates and systems don’t close off light coming through at the exit.

Arrowquip’s 3E Q-Catch head gate allows light through to utilise natural animal behaviour.

Dr Grandin recommends farmers experiment with different lighting sources and LED lighting, but to make sure they don’t flicker.

It’s also important to avoid the “dark movie theatre” effect, which is caused when an animal is expected to move from a sunny crowing pen into a dark working system.

#6 Animals will look right at what they don’t like in a handling facility

If cattle are balking at something in a handling facility, “they will show you the stuff they don’t like,” says Dr Grandin.

According to her, a calm animal will stop and look directly at something that is bothering them. This gives farmers and opportunity to assess their handling facility to see what is causing the issues.

A large abattoir in the US was having issues with cattle getting halfway up the race and stopping. Dr Grandin advised them to take a calm group through and to pay attention to where they stopped and assess their behaviour and the area. It ended up being leftover lights stored at the edge of the building from a construction project.

#7 Use inexpensive materials to experiment with changes

Rather than making assumptions and then investing time and resources into making immediate big changes to a handling system, Dr Grandin recommends farmers experiment with simple tools like portable lighting and cardboard.

#8 Invest in non-slip flooring

“I cannot emphasize this enough. In all cattle handling facilities – no matter where they are – the importance of non-slip flooring,” says Dr Grandin.

Slippage is a major point of agitation for animals but also jeopardizes safety. While grooved concrete flooring is a good option, Dr Grandin cautions that it does wear over time and at a gradual enough rate that it is hard to notice.

Rubber mats or woven tire mats are especially good options for cattle crush exits.

With all flooring, visual contrast between materials must be avoided to prevent animals from balking. If there is contrast, Dr Temple recommends spreading a uniform material like dirt over the floor to cover up any contrasts.

#9 Work cattle in small groups

The amount of cattle brought into a forcing pen/tub should never exceed filling the pen halfway full. Dr Grandin also recommends timing groups of cattle so there is room for the majority of them to enter into and move up the race.

If the forcing pen is filled too full and/or there is no room for them to move up the race, cattle will turn around away from the race entry.

“Good handling is going to require a lot of walking to move up small groups of animals,” she says.

#10 Use scoring to keep a record of changes made to a handling system

Dr Grandin recommends scoring cattle on the following before and after any changes are made to a facility to improvements or regressions can be assessed:

Vocalization when restrained

Balking

Slips and falls

Animal exit speed from crush

When applied pressure is required to move cattle through the race

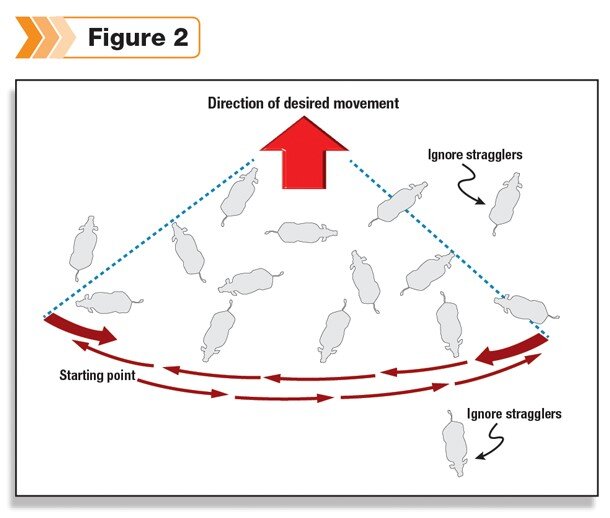

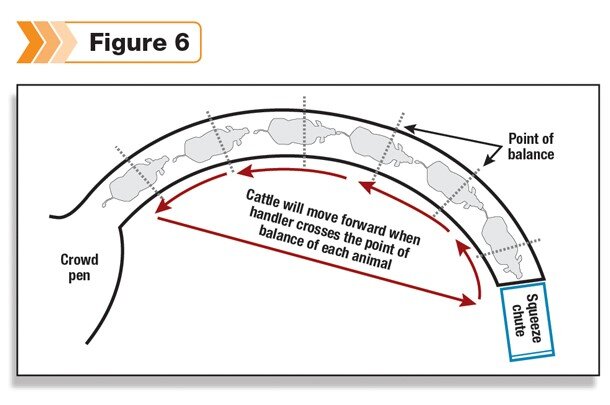

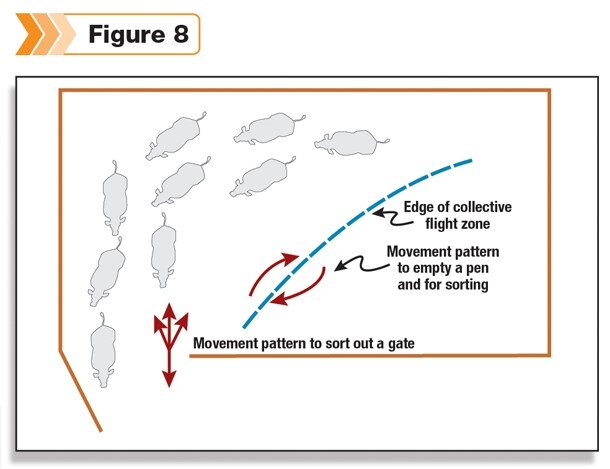

#11 Cattle move based on flight zone, pressure zone and point of balance

Flight zone – This is what causes an animal to move away from a handler and is an animal’s safety zone

Tame animals will have no flight zone

Calm animals will have a smaller flight zone

Pressure zone – This is when an animal will turn and face the handler

Point of balance – This is at the shoulder and will dictate which direction an animal will move.

Dr Grandin’s low-stress cattle handling webinar with AHDB goes into more detail on these points and explores other areas of cattle handling. To learn more, watch the “Stress-free stockmanship with Temple Grandin” webinar.

Arrowquip appoints Wise Agriculture as Scotland’s cattle handling equipment distributor

Arrowquip appoints Wise Agriculture as Scotland’s cattle handling equipment distributor.

Wise Agriculture has been appointed Scotland dealership rights for Arrowquip’s cattle handling equipment portfolio.

Wise Agriculture has been named the Arrowquip supplier to Scotland. The vast cattle handling equipment portfolio includes the flagship Q-Catch manual squeeze crush range, the Q-Power hydraulic range and mobile cattle handling systems.

The extensive product offering consists of the renowned Q-Catch manual squeeze crush and Q-Power hydraulic squeeze crush ranges, along with a suite of fixed and mobile cattle handling products that include race sections, sweep pens and portable cattle handling systems.

Located in Winnipeg, Canada, Arrowquip is a global leader in cattle handling equipment, combining engineering with animal behaviour to create products to improve safety, efficiency and quality.

“Arrowquip’s innovations are never ending as we work to create solutions for farmers to improve both the day-to-day and long-term outlooks of their businesses,” says Russell Evans, UK regional manager for Arrowquip. “Wise Agriculture shares our mission in not only providing British farmers with the tools they need to improve the safety and efficiency of cattle handling but also delivering gold-standard customer service. This is essential as warranties on some of our crushes reach 15 years, with specific working components reaching a lifetime.”

Based near Richmond, North Yorkshire, Wise Agriculture was founded in 2018 by livestock farmers Edward and Laura Wise. The company offers nationwide services to beef, dairy and sheep producers in premium livestock handling, data recording and animal welfare solutions.

“Wise Agriculture was founded on the principles of efficiency, innovation, practicality and quality in both the way we work and the products we supply. Arrowquip has been an important partner in this mission since the beginning,” says Edward Wise, managing director for Wise Agriculture. “Our new appointment will allow us to further improve Arrowquip customer experience for Scottish farmers. We already have a strong customer base of Scottish farmers and look forward to increasing our service to the country.”

Since its establishment, Wise Agriculture has taken on UK distribution rights for Landquip NZ’s Porta-Yards sheep handling equipment and also supplies Tru-Test weighing and EID products and AgriCow Rotating Cow brushes.

To learn more about Arrowquip’s cattle handling equipment offering, visit wiseag.co.uk.

Young Welsh couple win Rumenco’s Porta-Yards mobile sheep handling system giveaway

Young farmers and newlyweds Luke and Beth Watts of Pembrokeshire are the winners of Rumenco’s prize draw for a 3.0m Porta-Yards mobile sheep handling system from Wise Agriculture.

From left to right: Edward Wise of Wise Agriculture, Luke Watts and Amy Wright of Rumenco. Luke and Beth (not pictured) Watts were the winners of Rumenco’s giveaway of a 3.0m Porta-Yards from Wise Agriculture.

Coming from agricultural backgrounds, both Luke and Beth have chosen agricultural careers with the end goal of one day farming full-time for themselves. As they work towards this long-term dream, a lot of graft is involved for the couple to make this happen. While both work full-time jobs, they also run their own flock of 100 pedigree Llanwenog sheep and Beltex cross Texel ewes. The Watts market their lamb direct to consumers through meat boxes and are also in partnership with a family-owned catering trailer where lamb is sold under the Made at Moithan brand.

“Winning the Porta-Yards in the Rumenco draw has been a game-changer for us,” says Beth. “We didn’t have the flock size or resources to justify investing in a high-quality mobile sheep system. This has improved our sheep handling so much and is going to make it possible for us to scale more efficiently when the time comes.”

With the couple’s nutritional programme focused on making the most of available forage, spring and summer farm work is primarily made up of moving electric fences and managing grass rotations in the mornings and evenings.

“Time is very tight for us. The yard is going to make things so much more efficient as we graze this year, allowing us to pull fat lambs directly off grass the morning they need to go to market without needing to bring them into the yard to sort out,” adds Luke.

Aside from their developing agricultural careers and farming work, the couple is also highly involved in the farming community. Both are officeholders for the Pembrokeshire Agricultural Society, with Luke serving as an ambassador and Beth as a Pembrokeshire Agricultural Show governor. Beth is also involved with Cows on Tour, a Welsh farming organisation that hosts UK primary schools on farms and takes livestock and machinery to schools to teach children about farming and where their food comes from.

In January this year, Luke and Beth were married after meeting at the Royal Welsh Winter Fair in 2019.

According to Amy Wright, product manager for Rumenco, the company is excited the prize draw went to a young couple working towards building their futures in sheep farming.

“We are excited the Porta-Yards mobile sheep handling system has gone to such a deserving couple who are truly going to benefit from having a piece of kit like this given to them. Our nutritional supplements are developed to give both flocks and farming businesses longevity in the future – it is great to see Rumenco further support young farmers who will be having a generational impact on the industry,” she concludes.

Application guide for the FETF grant: Animal Health and Welfare

England livestock producers can now submit applications for the Animal Health and Welfare portion of the 2023 Farming Equipment & Technology Fund.

England livestock producers can now submit applications for the Animal Health and Welfare portion of the 2023 Farming Equipment & Technology Fund.

Click here to fill out the application.

The FETF 2023 portal will remain open from March 23 to June 15 at 11:59 am.

The FETF fund is for grants between £1,000 and £25,000.

Filling out the application

When filling out the application, the RPA advises all questions are filled out in one sitting and the webpage is not closed until you have submitted your application.

The RPA encourages applicants to submit as early as possible so any errors can be fixed as needed.

This is a competitive grant and not all applicants will receive funding.

Information to have ready:

Note – The below should be updated with the Rural Payment service before application. If updates or registration is required, click here.

· Customer Reference Number (CRN) – as registered with the Rural Payments service

· Single Business Identifier (SBI) – as registered with the Rural Payments service

· Email address – as registered with the Rural Payments service

· Business name

· Business address and postcode

· Companies House Number if registered as a Limited company

· VAT number if VAT registered

· Total hectares of farmed and managed holdings associated with your SBI

· Number of employees

· Farm assurance and livestock health scheme details

The FETF Animal Health and Welfare application requires additional information:

· FETF number and category to products applying for (an extensive list can be found here)

· Date and details of last vet visit to farm (RPA says this will not affect grant applications)

· Estimation of the number of livestock kept, species, sex and age

· County Parish Holding (CPH) number

Note – If the application is going to be submitted on an applicant's behalf by an agent, permission levels must be set to “Make legal changes” or “Full permissions.”

Grant recipients

The RPA will email applicants to let them know if they have been awarded funding or if they have been denied.

Recipients will receive a Grant Funding Agreement (GFA) and a claim form that will require them to accept the funding offer on the Animal Health and Welfare portal.

Once the GFA has been accepted, recipients can make purchases and accept deliveries of equipment. To allow for auditing, grant purchases cannot be made in cash.

Keep detailed records of all receipts and invoices to submit as evidence when making your claim.

Unlike other grant schemes, multiple product quotes are not required.

Click here to read more about FETF terms and conditions, including site visits.

Making FETF equipment purchases through Wise Agriculture

Wise Agriculture offers a wide range of livestock handling, weighing and welfare equipment qualified for FETF funding.

All of our equipment is available for nationwide delivery.

We are already ordering stock ahead and working with suppliers for short lead times. If you’d like to purchase any of our equipment, please contact us ahead of being notified about your grant acceptance to let us know which equipment you will be purchasing if accepted. This will allow us to ensure product availability and put you on a reserve list. If you do not receive the grant, you are not obligated to complete the purchase.

Eligible equipment from Wise Agriculture

Wise Agriculture has a wide range of cattle, sheep and weighing and EID equipment eligible for the FETF grant. Click the items below to learn more about equipment and to request a quote.

Sheep

3.0m Porta-Yards mobile sheep handling system

· FETF number: FETF69

· Grant amount: £3,568

Cattle

Q-Catch 87 manual squeeze crush

· FETF number: FETF61

· Grant amount: £2,060

Q-Catch 74 manual squeeze crush

· FETF number: FETF61

· Grant amount: £2,060

107 Q-Power hydraulic squeeze crush

· FETF number: FETF60

· Grant amount: £4,360

104 Q-Power hydraulic squeeze crush

· FETF number: FETF60

· Grant amount: £4,360

· FETF number: FETF62

· Grant amount: £252

Q-Catch mobile cattle handling system

· FETF number: FETF56

· Grant amount: £5,570

Arrowquip fixed cattle handling system: Forcing pen, race, sliding race gates

· FETF number: FETF57

· Grant amount: £4,102

AgriCow rotating pendulum cow brush

· FETF number: FETF98

· Grant amount: £600

AgriCow swinging brush for calves

· FETF number: FETF99

· Grant amount: £386

Weighing & EID

Tru-Test XRP2 EID panel reader for sheep

· FETF number: FETF74

· Grant amount: £597

Tru-Test XRP2 EID panel reader for cattle

· FETF number: FETF68

· Grant amount: £620

· FETF number: FETF78

· Grant amount: £348

· FETF number: FETF78

· Grant amount: £348

· FETF number: FETF79

· Grant amount: £358

Arrowquip adds two new units to its Q-Catch mobile cattle handling range

The new units – Q-Catch 748 and Q-Catch 7416 – feature the Q-Catch 74 Series manual squeeze crush along with the Easy Flow Adjustable Cattle Race in one towable unit allowing farmers to transport their cattle handling system anywhere work needs to be done.

Arrowquip has added two new products to its extensive Q-Catch mobile cattle handling range, giving beef and dairy producers more options to improve cattle handling safety and efficiency anywhere on their farms.

The new units – Q-Catch 748 and Q-Catch 7416 – feature the Q-Catch 74 Series manual squeeze crush along with the Easy Flow Adjustable Cattle Race in one towable unit allowing farmers to transport their cattle handling system anywhere work needs to be done. The 748 features an 8’ Easy Flow Race, while the 7416 gets a longer 16’ race.

Both units are manufactured with a first-grade steel top and bottom frame and feature a tractor tow bar and manual jacks. A five-year guarantee is standard, with lifetime guarantees on the crush’s rubber floor, rump fingers, squeeze locks and headgate locks.

Other features of the Q-Catch 74 Series crush include multiple access points with full-side horizontal opening top and bottom doors which can be pegged together and operated as one, removable top gates, and a drop-down and removable needle access door for TB testing. It also has a textured rubber floor that features a lifetime guarantee.

The 748 features a single 8’ adjustable race, while the larger 7416 uses two 8’ sections to create a 16’ length. Sheeted sides with removable top blinder panels keep cattle flow moving forward by preventing cattle from being distracted from activity outside the race. A simple pull rope allows the race width to be widened or narrowed to suit different sizes of stock.

An optional weigh platform kit fits within the race and supports Tru-Test and Gallagher loadbars.

Learn more about the 748 and 7416 and get a quote

“Arrowquip mobile cattle handling units have been a game-changer for UK beef and dairy producers by allowing for uncompromised cattle handling anywhere on the farm,” says Edward Wise of Wise Agriculture, UK dealer for Arrowquip equipment. “Whether it is being used as part of a fixed handling system in the farmyard or for TB testing in a field, these mobile cattle handling units will help improve the safety and efficiency of cattle handling for any livestock farm.”

Wise Agriculture delivers nationwide and has units in stock for immediate delivery. To learn more about the Arrowquip mobile cattle handling systems from Wise Agriculture, visit wiseag.co.uk.

Key features

The Q-Catch 74 Series is the mid-range cattle crush in the Arrowquip manual squeeze offerings. It features the 3E Q-Catch Head Gate with a vertical bar design that allows light to enter the front of the crush when the gate is closed to draw cattle forward without force. The infinite lock headgate and parallel squeeze will secure in any position – allowing a small calf or a large bull to be worked on without the need for adjustments. A sliding headgate handle allows the headgate to be operated anywhere along the working side of the crush, enabling operators to run the rear sliding door and headgate simultaneously.

Wise Agriculture appointed as the UK distributor for Landquip NZ’s sheep handling range

As of January 1, 2023, Wise Agriculture has been appointed sole distribution rights for Landquip NZ’s sheep handling equipment portfolio. This currently consists of the Porta-Yards mobile sheep handling range.

As of January 1, 2023, Wise Agriculture has been appointed sole distribution rights for Landquip NZ’s sheep handling equipment portfolio. This currently consists of the Porta-Yards mobile sheep handling range which includes the 2.5m Fork Lift, 3.0m, 4.5m and Small Flock Kit sheep yards.

According to managing director Edward Wise, the appointment will drive innovations for the UK market.

“We are already working closely with Landquip NZ’s research and development team for innovations to enhance the existing product range and for new products to fill the gap in the market,” says Mr Wise.

Based near Richmond, North Yorkshire, Wise Agriculture offers nationwide services to beef, dairy and sheep producers in premium livestock handling, data recording and animal welfare solutions. Established in 2018, Wise Agriculture is also a leading UK dealer for Arrowquip cattle handling equipment and Tru-Test weighing and EID products and has recently added AgriCow Rotating Cow brushes to its offering.

“Our philosophy for the products we carry and the way we conduct business has been centered around efficiency, innovation, practicality and quality. If a product or way of working does not fit into this ethos, then it is not right for our business or our customers,” says Mr Wise. “Landquip NZ’s quality engineering and emphasis on customer service have made them an excellent partner in servicing UK livestock farmers.”

Located in Hastings, New Zealand, Landquip NZ has engineered aluminium horticulture and livestock products for nearly 30 years for New Zealand, Australia, Europe, Japan, the United Kingdom and the United States.

To learn more about Landquip NZ’s sheep equipment offering, click here.

Farming Equipment and Technology Fund application for sheep and cattle handling equipment through the Farming Investment Fund grant scheme

Livestock farmers in England have from November 16, 2021 to January 7, 2022 to apply for sheep handling equipment and cattle handling equipment as part of the Farming Equipment and Technology Fund section of the Farming Investment grant scheme. Here’s everything you need to know.

Livestock farmers in England have from November 16, 2021 to January 7, 2022 to apply for sheep handling equipment and cattle handling equipment as part of the Farming Equipment and Technology Fund section of the Farming Investment grant scheme. Here’s everything you need to know.

The RPA has opened its Funding Investment Fund grant scheme, making available £27 million to farmers, growers, foresters and related contractors.

Farming Investment Fund is split into two categories:

Farming Equipment and Technology Fund

For grants £2,000 to £25,000

Available for equipment, technology and infrastructure to improve farm productivity

Farming Transformation Fund

For grants between £35,000 to £500,000

Available for larger investments involving water management, farm productivity improvement and adding value

This guide will focus on the Farming Equipment and Technology Fund (FETF). For more information on the Farming Transformation Fund, click here.

Farming Equipment and Technology Fund Guide

FETF Application deadline

November 16, 2021 to January 7, 2022 at noon

Funding available

Minimum of £2,000 with a maximum of £25,000

Those eligible

Farmers, growers and related contractors who service the arable, dairy, horticulture and livestock sectors

Removal of the “all or nothing” rule

In the previous Countryside Productivity Small Grant, applicants were only eligible for funding if they purchased everything they applied for. Taking industry feedback on board, the RPA has removed this “all or nothing” rule for FETF to allow case-by-case review of item removal. Minimum spend must still remain at £2,000.

Contractor eligibility

Contractors in livestock, dairy, arable and horticultural industries are now included on the list of eligible applicants

To apply for the FETF, click here.

Eligible Livestock Handling and Weighing Items

Equipment must meet specific criteria outlined by the RPA. Click here to view specifications.

Cattle Handling Equipment

Hydraulic Cattle Crush – or Pneumatically operated

Mobile Cattle Handling Systems

Foot Trimming Add-On to Cattle Crushes

Automatic Cattle Crush

Specialist Foot Trimming cattle Crush

Calving Gate

Cattle Auto ID Shedding Gate (auto drafting)

Sheep Handling Equipment

Fixed Sheep Handling Systems

Sheep Handler

Automatic Weighing and Drafting Crate for sheep

Sheep Conveyor

EID Panel reader for sheep

Electronic Weigh Crate for sheep

Weighing and EID

Weigh bars and weigh platforms for weighing livestock

Weigh bars or platform for animals less than 300 kg

EID Handheld Recorder Device

EID Handheld Device (stick reader)

Workshop: Research and homemade elements paying off in flexible handling system

Following a fire that devastated the milking parlour in 2019, Rob Smirthwaite turned away from milking cows to rearing dairy heifers and store cattle on his 162 hectare farm in Well, Yorkshire.

With plenty of research, new equipment and recycling of existing components, one Yorkshire farmer has built a versatile and efficient handling setup for his heifer rearing and store cattle business. Farmers Guardian Alex Heath finds out more.

Photos courtesy of Alex Heath, Farmers Guardain

“We wanted to have a system that was easy to use and could handle everything from weanlings to stock bulls with relative ease. Having it enclosed means we can keep working even when the natural light goes, such as when we are TB testing the herd.”

- Rob Smirthwaite

Following a fire that devastated the milking parlour in 2019, Rob Smirthwaite turned away from milking cows to rearing dairy heifers and store cattle on his 162 hectare farm in Well, Yorkshire.

With limited handling facilities to manage his 800 head of cattle, a significant proportion of which are dairy replacements, he set about researching and installing a bespoke system, designed to make husbandry tasks simpler.

While the base of the new facility is Canadian-built Arrowquip equipment, plenty of fabrication has been done around the system, improving cattle flow and handling safety.

The handling system sits on the site of the old parlour, with a new portal frame building housing it, providing shelter from the worst of weather and lighting for jobs that run into the night.

Mr Smirthwaite explains; “We wanted to have a system that was easy to use and could handle everything from weanlings to stock bulls with relative ease. Having it enclosed means we can keep working even when the natural light goes, such as when we are TB testing the herd.”

With cattle housed around the handling system, they enter the handling system through the old holding yard, before turning 90 degrees into a circular forcing pen. A neighbour of Mr Smirthwaite has fabricated several gates to fit into the shed, directing cattle flow and making it safe for those working. The first gate has an integral personnel gate that provides easy entry to the holding pen and, crucially, quick egress if an animal turns.

“While the dairy heifers are generally easy to work with, the occasional suckler bred beast can be temperamental, so having a quick escape is important. Once they are in the forcing pen, they can only travel in one direction, towards the crush,” says Mr Smirthwaite.

Close attention has been paid to the positioning of the system, deliberately orientated so cattle travel towards the light. “Initially we were going to have the cattle enter through the existing doorway, however, after some research we thought the flow would be better heading towards the light.”

The system was supplied by Richmond-based dealer Wise Agriculture, which sent various configuration designs to Mr Smirthwaite. The key to the design was making it versatile, by incorporating two crushes into the system; Mr Smirthwaite’s existing Bateman crush, used for foot trimming, and a new Arrowquip Q-Power 106 Series hydraulic squeeze crush, complete with weigh bars.

Both crushes have their uses says Mr Smirthwaite. The Arrowquip is used for general tasks, while the Bateman is reserved for hoof care.

To facilitate both crushes, a splitting gate was positioned immediately after the forcing circle. Cattle heading to the squeeze crush have a straight run through two, 2.4 metre race sections, while those heading to the foot trimming crush branch off at 45 degrees, before the race straightens and runs parallel to the other.

“It was important for us to have both crushes, as the squeeze does not lend itself to foot work. We get the odd case of digital dermatitis which requires quick treatment to clear it up, so having a crush that can easily lift a foot is needed,” he says.

Mr Smirthwaite says the squeeze crush is well designed and easy to use. “I really like the design of the crush. It has pieces of rubber throughout; on the hinges, bars and floor which stops any rattles and is near silent in operation. The configuration of gates is excellent, allowing access to all areas of the animal, ideal for the range of tasks we carry out, and having the hydraulic squeeze function means we can nip the sides in if an animal starts wriggling. The only thing I will be adding to it is a sternum bar to stop some of the steers dropping to their knees when nearing the head yoke,” he says.

The hydraulic motor used to run the rear gate, head yoke and squeeze function is housed in the old dairy room, with oil piped to the crush.

The width of the Arrowquip races can be altered by way of pins and five holes on either side of the top of the race, taking the width from 750mm to 458mm, allowing all cattle on the premise to use the system, without the room to turn around.

Mr Smirthwaite says the farm made the conscious decision not to concrete any of the elements into the ground, in case they wanted to reconfigure it at any point. In addition, he says the £30,000 investment would be hard to remove in the future, if they wanted to replace any of the elements. Likewise, he did not want to drill into any of the steel work and allow muck to contact unprotected steel work. Instead, he fabricated a series of bracket that wrap around the bottom rails and are bolted into the floor, holding the system in place.

Underneath the crush, Tru-Test weigh bars have been installed. “We buy and sell a lot of the cattle privately, so knowing the weight give us and the buyer a fairer price for the cattle. It is also good to see the performance of the dairy heifers and allows us to make decisions about the quality of the stock we are buying and where the best performing stock comes from,” adds Mr Smirthwaite.

Dairy heifers are served to Aberdeen Angus bulls at 14 months. The aim is to have them sold and calving in their new herds before two years old. The Angus is used for calving ease and high calf value, says Mr Smirthwaite.

With more cattle to load than previously experienced, Mr Smirthwaite says the loading area had to be addressed. “We used to load out of the holding yard, but it was always awkward to get an artic lorry backed in properly. Coupled to that, the cattle never really wanted to go up the ramp and having a large group could prove troublesome.

A single file passage way is used to load cattle for transport.

“While researching the handling system, I noticed in the US, New Zealand and Australia the lorries generally had a single door for loading and a single file chute. Cattle flow looked good so we thought of ways we could incorporate that into our setup.”

Using existing rails from the milking days, a single file walkway was made. Lorries back up the chute and cattle walk up the ramp with little encouragement, reports Mr Smirthwaite. “Because the cattle follow each other through the loading chute, they seem calmer and once the first animal is up the ramp, the rest follow, which has made loading much quicker and easier.”

Washing down also came under scrutiny. With the bulk tank now surplus to requirements, Mr Smirthwaite fitted a volume pump to the top, allowing him to give the handling system a quick wash each time it is used, keeping it looking fresh. In addition, LED lighting was installed in the roof of the shed, providing plenty of light when natural light disappears, he says.

Through a combination of purchased equipment and recycling of existing infrastructure, Mr Smirthwaite says he has developed an easy to use handling system that take the stress out of doing husbandry tasks. A bit of thought on how to fit all the elements together has resulted in an effective and efficient way of handling and loading cattle. “If jobs are easy to do, as they now are through our system, they get done on time, without any stress to the cattle, my helpers and myself,” concludes Mr Smirthwaite.

This article originally appeared in Farmers Guardian and was reposted with permission.

Cattle handling and weighing products that qualify for Scotland’s Sustainable Agriculture Capital Grant Scheme (SACGS)

Applications for the Sustainable Agriculture Capital Grant Scheme (SACGS) closed on October 11th.

Approved applicants must buy, pay for in full and have installed of all items by midnight on March 31, 2021.

Product availability: Wise Agriculture is receiving weekly shipments of cattle handling equipment to keep up with customer demands. We offer nationwide delivery.

Cattle handling and weigh equipment items that qualify:

Manual Squeeze Crush

Specifications:

Manually operated with full length head yoke

Sides of crush that open completely

Sliding rear gate

Galvanised or powder coated

Anti-backing facility

Disqualifications:

Painted crushes

Q-Catch 87 Manual Squeeze Crush

Nylon bushings on all pivots and hinges make this crush exceptionally quiet to operate.

3E Q-Catch Yoke Gate features slats to draw cattle forward with light

Head gate and parallel squeeze operate on an infinite locking system, requiring no adjustments

Operate the head gate at any point alongside the crush

Full side access

GoodYear rubber floor

Powder coated

7-Year warranty

Q-Catch 74 Manual Squeeze Crush

Most economically friendly cattle crush available that doesn’t compromise quality or safety standards.

3E Q-Catch Yoke Gate features slats to draw cattle forward with light

Head gate and parallel squeeze operate on an infinite locking system, requiring no adjustments

Operate the head gate at any point alongside the crush

Full side access

Textured steel floor

Powder coated

7-Year warranty

Click here to learn more about this crush.

Head scoop

Specifications:

Prohibit head moving side-to-side

Q-Catch Cattle Head Scoop

Push-pull operation

Scissor style pressure holds heads completely secure

Height adjustable

7-Year warranty

Electronic weigh system (Indicators)

Specifications:

Digital recording device

Functionality to operate with auto drafting

Ability to connect to a computer or mobile device

Weigh bars are a separate grant item

TruTest EziWeigh 7i

EID Compatible

Internal memory

Shows weight gains since previous session

Can display drafting directions based on weights

TruTest XR5000

EID Compatible

Colour Screen

Full keypad for data entry

Visualize performance with on screen graphs and charts.

Useful for full performance recording herds as data is easy to enter at the crush

Weigh bars

Specifications:

Operate with cattle crushes, sheep or pig crates

Can weigh at least 2,000kg

TruTest HD5T Loadbars

5 ton capacity

Sealed to protect against water ingress

Will bolt directly to Arrowquip cattle squeeze crushes

EID stick reader

Specifications:

RFID technology

Scans tags and stores data

Read HDX, FDX B or UHF tags

TruTest XRS2 Stick Reader

Reads up to 1,000 tags/min

Wireless connection to TruTest weigh scales

Bluetooth or Windows PC connection

19-hour battery life (rechargeable)

Reads ISO HDX and FDX-B tags

Accelerating genetic progress with embryo transfer

Veterinarian and beef farmer Dr Gerard te Lintelo is making rapid genetic progress to grow his Shorthorn herd. Here’s why an Arrowquip manual squeeze crush and full handling system is important to his breeding programme.

Veterinarian and beef farmer Dr Gerard te Lintelo is making rapid genetic progress to grow his Shorthorn herd.

“Breeding with average only produces average. The quickest way of getting to where we want to be is to constantly improve generations.”

- Dr Gerard te Lintelo

From the moment of its own conception to the point of putting a live calf on the ground, the genetic turnover time in cattle is around 2 years and 9 months – making genetic progress a strategic long game.

When Dr Gerard te Lintelo, a practicing veterinarian, purchased a farm on the on the outskirts of Wolsingham in Durham three and a half years ago, this prolonged period of genetic evolution was a major obstacle for his plans of developing a pedigree Beef Shorthorn herd.

“From the start, my plan has been to develop a base of pedigree genetics for commercial producers, focusing on traits like good feet, udders, efficiency, meat quality, fertility, calving ease and temperament,” says Dr te Lintelo. “I’m after producing profitable genetics for commercial beef producers.”

Dr Gerard te Lintelo and his son, William, work together to pregnancy detect recipient cows to determine which calves are natural service from the sweeper bull and which calves are from embryos. Recipients are scanned at 35 days pregnancy and then a sweeper bull is put in the same day.

After an initial purchase of five bred heifers, Dr te Lintelo decided to utilise embryo transfer (ET) to accelerate the development of his genetic base. Present day, his pedigree herd consists of 28 head of breeding females with plans to build it to around 150.

According to Dr te Lintelo, using ET to set up a herd has several advantages over using semen and/or natural service.

“With ET you have the ability to bring in top genetics from both maternal and paternal lines, whereas with using artificial insemination or natural service, this is limited to paternal lines,” he explains. “ET also takes down geographical barriers – allowing you to access the best of the best genetics from anywhere in the world,” he says.

Sourcing genetics from Australia and Canada, Dr te Lintelo says this has also helped improve animal performance.

“When it comes to a relatively closely linked genetic pool within a country, you can actually see internal heterosis when introducing new genetics from the same breed from unrelated lines. This goes on to contribute to offspring with more vigorous traits and improved health,” he explains.

Recipient cow management

While ET is an effective way to increase the genetic progress of a herd, it does not come without investment costs and risks. According to Dr te Lintelo, the average embryo costs £500 to purchase and averages a conception rate of 50% – not including vet and medicine fees.

Dr Gerard te Lintelo’s Arrowquip Q-Catch manual squeeze crush from Wise Agriculture allows handlers to operate the sliding rear gate and head gate at the same time, reducing labour requirements.

To maintain a profitable breeding programme even if an embryo doesn’t stick, risk is spread through the recipient herd. This starts with a careful evaluation of any recipient animals before they are enrolled into the ET programme.

“My recipients are Shorthorn and Angus crossbreds that have a good baseline of production genetics and high health status. Prior to entering the ET programme, I check their reproductive tract to ensure it is in working order.” he says. “Nutritional management of the recipient herd is also paramount, with cows receiving mineral boluses twice a year and the feeding programme consisting of high-quality grass and silage to maintain a body condition score of 2.5-3.0. Recipients also receive all vaccinations and anti-parasitic treatments prior to the start of the ET synchronisation programme.”

While these practices help to increase the embryo success rate, their quality genetics also act as an insurance policy.

“A significant hidden cost of any ET program is the delay in getting recipient animals in calf when the embryo does not hold. If an embryo doesn’t carry, it can be three to four months before the recipient cow is pregnant again. That amount of time and resource being put towards an unproductive animal quickly adds up,” he says. “I scan the recipients at 35 days pregnancy and then add a sweeper bull with the recipients the same day. So, rather than being left with an open cow, I will have most recipients in calf within 8 weeks after ET. These will then produce my next generation of recipients and male animals are sold as steers.”

Low stress handling

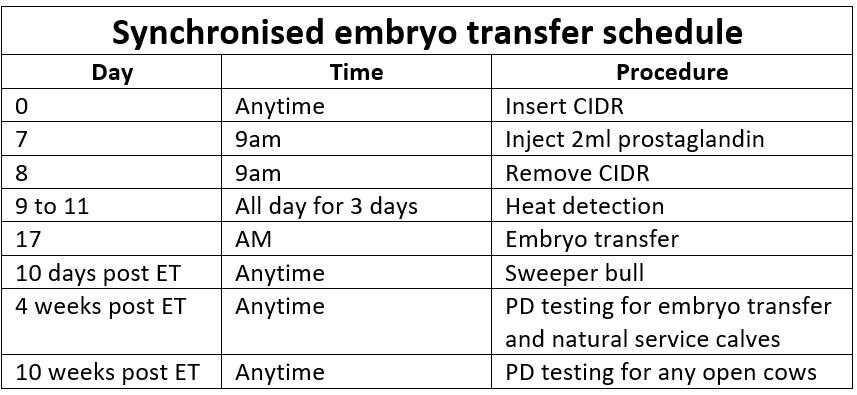

Currently, the operation is using a timed synchronisation protocol (see chart) that requires cows to be put through the handling system four times within 17 days. For peak fertility at ET, these processes must be done within specific time periods. Following ET, cows are put through the system two more times to detect pregnancy and to determine which calves are natural service from the sweeper bull and which calves are from embryos.

According to Dr te Lintelo, an investment into an Arrowquip cattle handling system, including a manual squeeze crush, forcing pen and race sections from Wise Agriculture that was designed to reduce stress and improve working efficiency has been essential to the success of carrying out the breeding programme.

“Stress cause by handlers and handling systems is detrimental to fertility and will cause a cow to either not breed or to abort her calf. And if cows don’t have a positive experience in the handling system, they will become sour and harder to work in the future,” he says. “Our Arrowquip cattle handling system was designed based on animal behaviour research, resulting in a very quiet and easy flowing system that allows us to accurately implement breeding protocols.”

Aside from the intense handling schedule as part of the breeding programme, the entire herd is handled regularly for performance recording, vaccinations, bolusing and TB testing.

“From a young age, we will run calves through the handling system multiple times without doing any procedures to get them familiar with it,” says Dr te Lintelo. “When we are doing procedures, especially if it is something unpleasant like being stuck with a needle, we will feed them some concentrate while they stand in the crush. Little things like this don’t require a lot of effort and go a long way towards reducing stress levels and improving their willingness to be handled in the future.”

Continuing genetic progress

As his herd numbers increase, Dr te Lintelo’s plan is to produce embryos from the top 20% of the females, with the bottom 20% going into his recipient herd. AI or natural service will be used for the middle 60% of the herd. Top performing bull calves will be developed and sold to pedigree and commercial producers for breeding, while culls are sold for fattening.

“Breeding with average only produces average,” he says. “The quickest way of getting to where we want to be is to constantly improve generations.”

This article originally appeared in the September 11th issue of Farmers Guardian and has been republished with permission.

Here’s everything you need to know about sheep and cattle handling equipment specifications for the Countryside Productivity Small Grant (CPSG) scheme

Qualifying sheep and cattle handling and weighing equipment for the CPSG scheme.

The recent announcement of the third and final round of the Countryside Productivity Small Grant (CPSG) scheme has opened funding for equipment and technology on English sheep, beef and dairy farms. The grant will cover up to 40% of equipment costs at a total minimum value of £7,500 and total maximum of £30,000. Applications must be received by midday on 4 November 2020.

Click here for application and payment details.

Product availability: Wise Agriculture has shipping containers of cattle handling equipment arriving weekly to ensure product stocks are available.

Livestock items that qualify:

Mobile sheep handling systems

Specifications:

Trailer mounted and integrated into the handling system to form part of the race

Minimum 250 head capacity

Comes with minimum of 20 hurdles for gathering/forcing pends and two side pens

Drafting and dosing race with ability to fit a foot bath

Road legal

Galvanised or powder coated metal work

Disqualifications:

Trailers that aren’t integrated as part of the race

Wooden elements such as the race floor or gates

Painted metalwork

3.0m Porta-Yards by Landquip NZ

The 3.0m Porta-Yard mobile sheep handling system by Landquip NZ has a 250 sheep capacity can be increased with an existing fence.

1.0m high alloy hurdles with a solid top section protects dogs legs and reduces jumping sheep

Hydraulic lift and lower

Hydraulic suspension

Forcing pen and gate

Manual squeeze cattle crush

Specifications:

Manually operated

Squeeze

Full length head yoke

Full side opening on both sides of the crush

Sliding rear gate that operates from both sides of the crush

Galvanised or powder coated metal work

Disqualifications:

Painted metalwork

Wooden floors

Q-Catch 87 Series Manual Squeeze Crush

The Q-Catch 87 Series manual squeeze cattle crush is easy and quiet to operate.

3E Q-Catch Yoke Gate improves cattle flow with light

An infinite lock head gate and parallel squeeze requires no adjustments

Head gate can be operated from anywhere along the side of the crush

Full side access

Textured rubber floor from GoodYear

Powder coated

7-year warranty

Hydraulic squeeze crush

Specifications:

Hydraulically operated on power-driven pump

Squeeze

Full length head yoke

Full side opening on both sides of the crush

Sliding rear gate that operates from outside of crush

Galvanised or powder coated metal work

Disqualifications:

Painted metalwork

Wooden floors

Rotating/rollover foot trimming crushes

Pneumatically operated

Hand/manually powered pump hydraulics

Q-Power 107 Series Hydraulic Squeeze Cattle Crush

The Q-Power 107 Series Hydraulic Squeeze Cattle Crush is world renowned for its quietness and ease of operation.

Spacing in the 3E Q-Catch Yoke Gate uses light to improve cattle flow

Single-phase hydraulic power pack

Curtain style front and rear gates

Power pack is mounted away from the crush

Control arm operates on either side of the crush

Removable panels plus opening top and bottom side doors give operators multiple points of access

GoodYear rubber floor

3-year warranty

Head scoop for cattle crush

Specifications:

Must restrict side-to-side head movement

Galvanised or powder coated metal work

Disqualifications:

Painted metalwork

Integrated head restraints supplied with a cattle crush as standard which cannot be purchased separately and retrofitted are not eligible under this item

Q-Catch Cattle Head Scoop

The Q-Catch Cattle Head Scoop uses a scissor action motion to securely hold the head in place.

Fits all crushes in the Q-Catch and Q-Power Series range

Simple push pull operation

Single lever control uses a dual friction lock with infinite adjustments

Adjustable height to fit any size animal

7-year warranty

Mobile cattle handling systems

Specifications:

Integrated road legal trailer

Manual or squeeze crush with locking head yoke

Race

Holding pen

Gathering pen

At least 10 gates/hurdles purchased with unit

Anti-backing at rear of the crush operated from outside

U-shaped rotating rump bar on a wheel

Sliding gate

All metal construction

Galvanised or powder coated metal work

Disqualifications:

Wood elements

Painted metalwork

Q-Catch 87 Series Portable Handling Systems

Incorporating Arrowquip’s manual and hydraulic cattle crushes, there are more than 37 different portable options available. The Q-Catch 87 Series Portable Handling system is a market favourite.

Features the Q-Catch 87 Series manual squeeze crush

Infinite locking head gate and parallel squeeze

GoodYear rubber floor

Adjustable width 2.4m (8’) race

Main frame beams that run from front to back of the unit are continuous pieces of steel with no joins

Manual Jacks as standard

12 months warranty

Wise Agriculture can also supply you with required gates and hurdles.

Fixed cattle handling systems

Specifications:

Corral and race-way handling facility to attach to a crush

Crushes are not included in this grant item but race must lead to a crush

Fixed to the ground by bolting to concrete or attaching to concrete supporting post

Minimum two metal holding pens

One circular metal forcing pen with internal radius of 2.4-5m

Covered sides with smooth material

Leads into curved race

Side covered race sections between 3-5m length

Sliding rear gate fitted at either end of race

All metal construction

Galvanised or powder coated metal work

Disqualifications:

Wood elements

Painted metalwork

Adjustable Easy Flow cattle races

Sheeted sides prevent distractions from outside the race

Simple lever system alters width

Available in 10’ sections which peg together or to a crush or tub

Optional anti-backing bars keep cattle moving forwards

Cann be set up as a double race using a double exit tub and merge sections

3E BudFlow® Tub

The Bud Box concept with the safety of a push gate. Cattle enter the BudFlow® at the front of the pen, When they naturally turn back, they will be headed right for the race opening. If necessary the operator has the option to use the forcing gate to empty the tub.

Single race exit, available in an 8’, 10’ or 12’ radius

The BudFlow® easily attaches to other Arrowquip products.

Wise Agriculture offers full system design. Click here for full fixed system offering.

Weigh bars and weigh platforms

Specifications:

Electric load bars or electronic weigh platform

Operate with digital weigh heads/readers

HD type load bars

Capable of weighing 2,000kg

Digital weigh heads/readers are separate grant items

Disqualifications:

Non electronic weighing systems

Tru-Test HD5T Load Bars

Heavy duty load bars, ideal for use under the heaviest of cattle crushes.

5 ton rated capacity

Sealed load cell protects against water ingress for outdoor use

Suitable for use with all current TruTest indicators

Will bolt directly to Arrowquip Q-Catch and Q-Power Series cattle squeeze crushes.

Electronic weigh systems

Specifications:

Digital weighing device

Record and display individual weights on screen

Operate EID readers and operate auto drafting systems

Connect to computer or mobile device to download data

Items relying on mobile device must include mobile device as part of purchase

Weigh bars are separate grant items

Disqualifications:

Group and automatic average animal weighing systems

Tru-Test XR5000

The most advanced weigh indicator in the TruTest range. Excellent farm management tool

Store up to 1,000,000 records in 1000 sessions

Up to 100 pieces of information for each animal

Up to 10 way drafting by any criteria

Track, apply and manage treatments including withdrawal periods

Calculate and visualise performances with on screen graphs and charts

Link to EID readers, auto-drafters and barcode scanners

Rechargeable battery with up to 13 hours of run time

Transfer information easily through bluetooth mobile app or directly to a Windows PC with the cable provided

Tru-Test EziWeigh 7i also qualifies. Click here for more.

EID panel reader

Specifications:

Permanently fixed to cattle crush or race

Static race reader with antenna and Bluetooth connection

Reads HDX and FDX B tags

Disqualifications:

Portable readers

XRP2 Panel Reader System

Fast and accurate reading of tags

Send directly to weigh system or record and download to PC

Plug and play

Reads ISO HDX and FDX-B tags

Automate your weighing routine to save time and money

Large and small antenna options with dual connection kits available

EID stick reader

Specifications:

RFID technology

Scan tags and store tag data

Wireless connection to devices

Reads HDX and FDX B tags

Tru-Test SRS2 Stick Reader

Fast tag reads (up to 1,100/minute)

Wirelessly connects with TruTest weigh scales

Easily transfer information using the Bluettoth smartphone app or Windows PC

Memory for 250,000 scanned tags

Rechargeable battery for up to 19 hours of use

Reads ISO HDX and FDX-B tags

The XRS2 Stick Recorder also qualifies. Click here to learn more.

Click here for the full list of qualifying items and specifications.

New Arrowquip crush range now available in the UK

Upping the standard of its world-renowned cattle handling equipment, Arrowquip is releasing four new squeeze crushes. Introducing the Q-Catch 87 Series and Q-Catch 74 Series manual squeeze crushes and the Q-Power 107 Series and Q-Power 104 Series hydraulic squeeze crushes.

The bar has been raised.

Arrowquip’s new Q-Catch 87 Series manual and Q-Power 107 Series hydraulic are the most robust line cattle crushes on the market.

Cattle handling equipment safety and efficiency is essential for beef and dairy producers looking to optimise herd performance.

“Whether it be mitigating injury of livestock and handlers, improving health programme protocols and daily liveweight gains or reducing production losses associated to stress, cattle handling equipment is going to have a long-term economic impact on beef and dairy herds,” says Edward Wise of Wise Agriculture, leading UK supplier of Arrowquip.

According to Steve Langrell, cattle handling expert lead on Arrowquip’s research and development team, the new range combines practical functionality with animal behaviour research.

“Arrowquip equipment improves handling safety and efficiency by working with – not against – the natural instincts of cattle,” explains Mr Langrell. “Combining this with customer feedback, trial work on our research farm and quality manufacturing, we have developed the most diverse and innovative range of cattle handling equipment on the market.”

Q-Catch Series Manual Squeeze Crushes

Arrowquip’s Q-Catch 87 Series manual squeeze crush operates with an infinite locking system so any size of animal can be secured without the need for adjustments.

The new Q-Catch 87 Series and Q-Catch 74 Series cover a greater demand from producers with different sized herds. With an industry leading seven-year warranty, the Q-Catch Series range ensures a quality investment.

Both crush lines feature the 3E Q-Catch Yoke Gate, a new curtain style head gate that uses light to improve cattle flow through the crush. Operating with an infinite locking system, any size of animal can be secured without the need for adjustments. The same locking mechanism operates the squeeze, easily holding the largest bull to the smallest calf.

Featuring a rear sliding door and ability to operate the head gate anywhere along the side of the crush, the Q-Catch Series is ideal for producers with limited labour resource.

“The Q-Catch Series has multiple access points, including top and bottom access doors that can be opened independently or together, and a needle door that provides generous access to the neck,” explains Mr Langrell. “This easy and safe access to the animal has made the Q-Catch Series a preferred option for many veterinarians for TB testing and pregnancy detecting.”

The heavier, more refined Q-Catch 87 Series has a textured floor made of virgin Goodyear rubber to keep cattle calm as they enter the crush. Pivots and hinges are engineered with poly bushings and slam latches are poly coated to reduce noise.

“Sudden movement and loud noises, such as clanging equipment or shouting, will kick in an animal’s fight or flight instincts and induce stress. This often leads to cattle not flowing through the system properly,” explains Mr Wise. “The calm environment provided by the Q-Catch Series and the ability for one person to operate the crush has allowed one of our Scottish customers to weigh cattle at a spot rate of 100 head per hour with only two people.”

A wide-range pivoting swinging arm allows for the crush to be operated on either side.