Making low-stress, safe work of cattle work

By Meranda Small, University of Idaho

The practice of low-stress handling is an economic decision as well as an animal welfare issue. It also is a practice that aids in getting a job done efficiently using fewer people, less time and preventing damage to facilities, which adds to costs.

When we get in a hurry or have some overeager or aggressive help, bruising and stress occurs, which will lessen carcass value as well as consumer confidence in beef products.

By practicing low-stress handling when working your cattle, you’re saving yourself time, money, lessening stress of the animal and, equally important, keeping yourself and help safe.

Let’s refresh on the practice of low-stress handling while gathering cattle to be worked and to remember the importance of crush side safety for cattlemen and cattle alike.

Stress is a state of physical, mental or emotional strain or tension resulting from exposure to a stressor. As cattle handlers we can cause, modify, increase or lessen stress in animals, with or without knowing it.

The idea behind low-stress livestock handling is to handle cattle in such a way as to lessen existing stress, create minimal or no additional stress and promote psychological well-being and physical health. Stressed cattle have poorer gain and reproductive performance as well as weakened immunity, all ultimately leading to more cost of production.

Before we get into handling techniques for open-area gathering, basics of animal behaviour needs to be understood:

Cattle want to see you

Cattle want to go around

Cattle want to be with and will go with other cattle

Successful low-stress handling incorporates flight zones as well as pressure zones in harmony with the animal’s natural instincts. Cattle are unable to see directly behind. Moving into their blind spot will cause them to turn to see what is pressuring them. This can be a benefit by changing the animal’s direction or a hindrance by preventing straight forward movement.

Because cattle are “prey animals,” they are naturally aware there is safety in numbers. Another fact to keep in mind is that cattle walk comfortably at 2 to 3 mph, while people walk at 3 to 4 mph, so take it easy.

In order to make successful movement of cattle occur, you’ll want to utilize their flight and pressure zones and point of balance, whether on one animal or on the herd.

In Figure 1, you’ll notice the point of balance for the animal falls at the shoulders; this is how the handler will pressure the animal to move forward or back. It is also indicated where to move to in order to initiate movement and then stop it.

Once the animal begins movement, reward it for “correct” movement by backing the pressure off a bit and removing yourself from the animal’s flight zone.

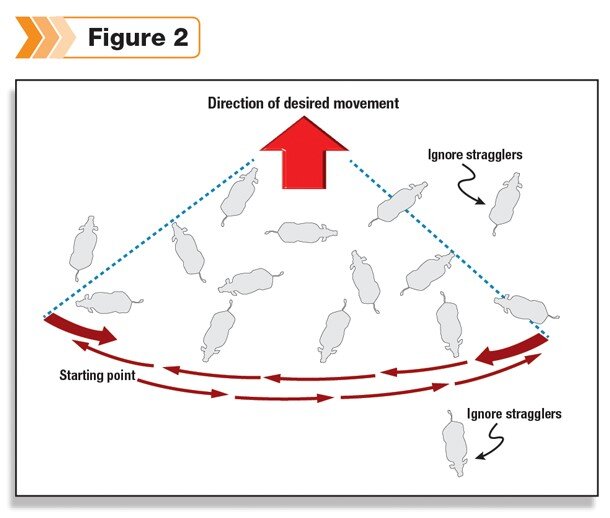

When you head out to gather from an open pasture, whether done by foot or four-wheeler, you’ll want to move slowly, working in a half-circle pattern with the point of desired direction being the middle of the quarter-circle.

Ignore those lone animals; that third basic instinct of theirs will kick in and they’ll eventually come with the herd. Figure 2 demonstrates this movement.

As cattle begin to move, back off to allow for their natural pace, keeping a light pressure but making sure to not get too close. You’ll have an idea if the pressure is too much if they are stopping and turning to look at you either out of fear or curiosity, both of which defeat your goal of getting to the corral.

As cattle start to trail, you will know if you are trying to move them too fast by them bunching at the tail of the herd. Also be aware that pressuring the side of the animal will cause them to speed up, a concept to keep in mind when deciding how quickly you want the herd to move.

Notice in Figure 3 that as the handler, you’re not to be directly behind when following but rather moving back and forth to stay in their sight.

Once you’ve arrived at the corral, your next goal will likely be to get the animals through a gate into the corral. You’ll want to act as a control valve for moving animals through the gate, not pushing a large number through nor encouraging a lightning-fast pace.

Utilize the animal’s natural instinct of wanting to go around when it comes to getting though the gate as well. Having one handler travel alongside the herd against the flow of traffic will encourage animals to move forward into the corral. Refer to Figures 4 and 5.

Success! You’ve brought in your herd, made it into the corral and did so in a low-stress manner, keeping cattle calm as well as yourself. A cattle commandment to keep in mind at the start of each day is “If you don’t have time to do it on cow time, you don’t have time to do it.”

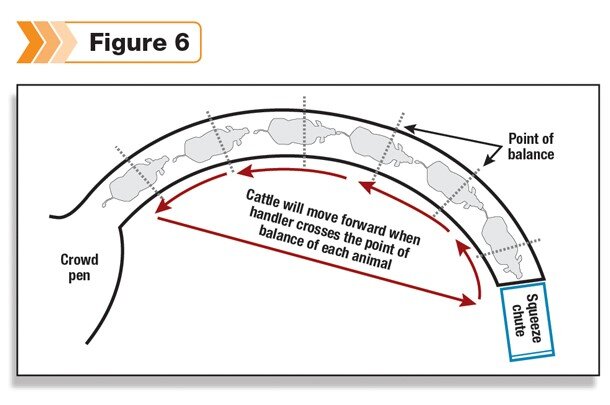

Each operation has their own processing setup that consists of a variety of sorting and holding pens, alleyways or whatever path you’ve created to get cattle to the crush. If you’re working with a tub, do not overcrowd and cram in as many head as will fit.

This really prevents movement and accomplishing the goal of getting animals into the alley. Whether your alley is curved or a straight shot, movement of cattle will occur by moving against them to enter each animal’s point of balance that will instinctively make them move forward.

Observe Figures 6 and 7 to gain a visual understanding of this concept.

This is not the time to get in a hurry or get flustered and start whooping and hollering or swatting at the cattle with a broken fiberglass prod pole while they’re confined. You’ll just wear yourself out and stress them out. Using proper movement in a quiet manner, the right way, will get cattle moving without encouragement of electric prods.

You’ve made it to the crush and can now go to work processing. Animals should walk into the crush – preferably not ram into the head catch. Now is not the time to forget crush side safety. Watch for pinch points where a hand or arm could get caught between the crush and body of the animal while giving a shot.

If approaching an animal near the head, don’t lean down into its space. Without warning, it may fling its head up and knock you out in the process. If your crush is manual rather than hydraulic, pay attention to handles and levers as cattle come into and exit the crush, ensuring you or your help doesn’t get accidentally hit by any of these.

It would also be good practice to check all the bolts and pins on movable parts prior to beginning crush work so as to prevent a crush side from falling down mid-processing.

Release the animal by slightly loosening the body squeeze; then open the head catch. The idea is that the animal will walk out calmly, perhaps hurried – but there are those animals that will bolt. Pay attention as the animal exits for flailing back legs.

All shots have been given, pest controls administered, implants applied, and it’s now time to kick the herd back out. For some, perhaps the animals were already “out” as they left the crush, but for others, they may have exited into a pen where they were held until all animals were processed.

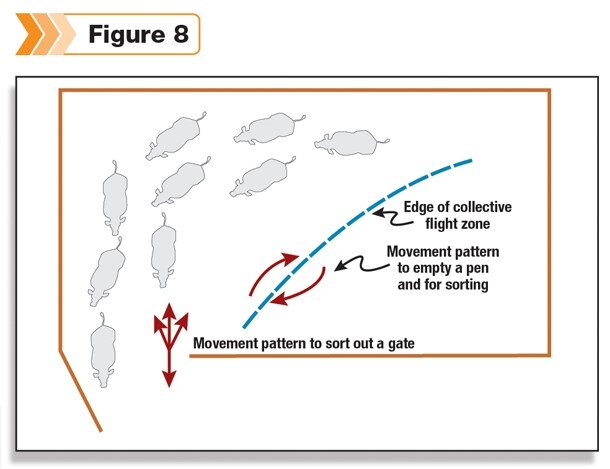

To push cattle out of the pen (Figures 8 and 9), enter the pen through the gate you want the animals to leave through. Remember, cattle want to go around you.

Find the herd’s point of balance to initiate forward movement toward the gate and then begin moving in a straight line, back and forth, moving forward in a zig-zag pattern to keep pushing toward the gate. Again, don’t worry about the strays and don’t chase the animals out.

This article originally appeared in Progressive Cattleman and has been published with permission.